Total Air Displacement Monitoring (TADM)

How to measure TADM curves and control liquid handling steps with them.

Total Air Displacement Monitoring (TADM) is an advanced feature designed to enhance the accuracy and reliability of pipetting processes in liquid handling systems. TADM uses pressure sensors to monitor the pressure inside each pipetting channel during both aspiration and dispensing, allowing for real-time detection of pipetting errors. This guide will help you integrate and utilize TADM within your application, ensuring precise and error-free liquid transfers.

Benefits of TADM

- Increased Safety: By monitoring pressure changes, TADM can detect and prevent potential pipetting errors.

- Enhanced Robustness: Ensures consistent pipetting performance across various liquids and volumes.

- Real-time Monitoring: Provides immediate feedback on the pipetting process, enabling prompt correction of issues.

When to Use TADM

TADM is ideal for:

- Single aspirations and dispenses for volumes above 10 μL.

- Multiple dispenses with individual aliquot volumes above 10 μL.

- Transfers of various liquid types, not limited to aqueous solutions.

TADM is especially beneficial in regulated environments and for development purposes, as it records every transfer step, allowing for detailed review and comparison of pressure profiles during and after method runs. This capability is invaluable for troubleshooting and ensuring stable transfers.

When Not to Use TADM

Avoid using TADM if:

- The volume to pipette is less than 10 μL, as pressure profiles may be inconsistent.

- You need to determine the exact pipetted volume or the amount of volume missing from a sample.

- The method involves variable volumes, making it impractical to create tolerance bands for each volume.

- You need to confirm the precision and trueness of the transfer, as TADM cannot provide these metrics.

Modes of TADM

- Recording Mode: The pressure inside the pipetting channel is recorded and stored.

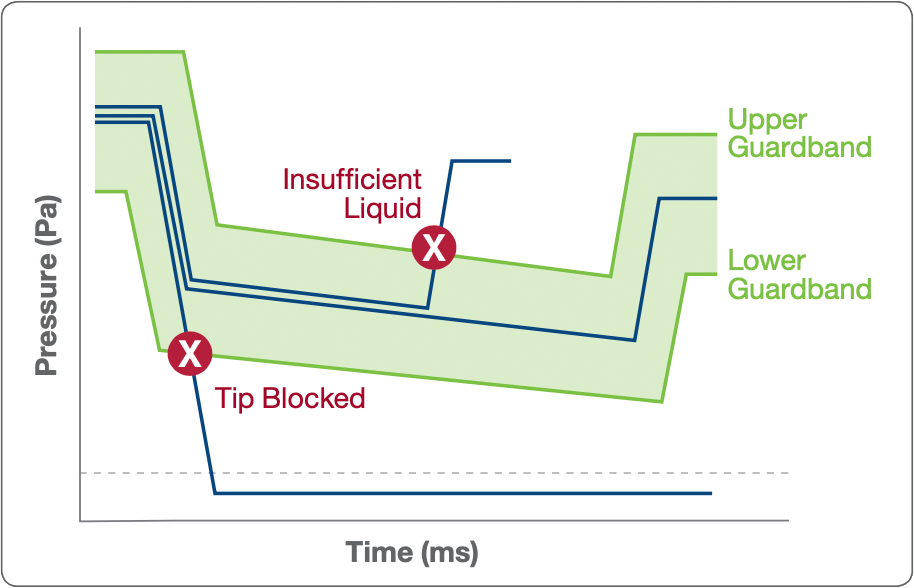

- Monitoring Mode: The recorded pressure is compared to a user-defined tolerance band in real time. If the measured value deviates from the tolerance band, the plunger movement stops, and software-dependent error handling is executed

Reading TADM Curves

Using TADM Guardbands

Guardbands are essential for active monitoring:

- Collect consistent pressure profiles for each volume transferred.

- Set upper and lower tolerance bands based on these profiles.

- Monitor for exceptions during runtime; deviations indicate potential errors.

Step 1: Create TADM Guardbands

from unitelabs.liquid_handling.hamilton import LimitCurve

# sequence of time (ms) and pressure (Pa) value pairs

upper_limit_curve = [(0, 2000), (500, 2000)]

lower_limit_curve = [(0, -2000), (500, -2000)]

tadm_guardband = await hamilton.pipettes[0].add_tadm_guardband(upper_limit_curve, lower_limit_curve)

Step 2: Read TADM Guardbands

tadm_guardband_uuids = await hamilton.pipettes[0].get_tadm_guardbands()

tadm_guardband = await hamilton.pipettes[0].get_tadm_guardband(identifier=tadm_guardband_uuids[0])

print(tadm_guardband)

# TADMGuardband(

# index = 0,

# identifier = "40e21e0f-bd91-4dd7-89e0-bce233e18fc3"

# upper_limit_curve = [(0, 2000), (500, 2000)]

# lower_limit_curve = [(0, -2000), (500, -2000)]

# )

Aspiration TADM Curve

Step 1: Enable TADM Recording

TADM is disabled by default. To enable TADM recording for an aspiration step, set the tadm_mode property either to TADMMode.ERRORS or TADMMode.ALL.

await hamilton.pipettes.aspirate(..., tadm_mode=hamilton.pipettes.TADMMode.ALL)

tadm_limit_curve: int = 0 on the aspirate method to choose an appropriate guardband by its index.Step 2: Read TADM Recordings

Each individual channel stores its TADM recordings. Read the data on each channel with get_tadm_data, e.g. for the first channel, use:

tadm_data = await hamilton.pipettes[0].get_tadm_data()

The returned data contains a measured pressure value in Pa for each 10ms.

- Plunger Movement Starts

- Pressure is High Enough to Overcome the Surface Tension

- The Liquid Starts to Flow into the Tip

- The Speed of the Rising Liquid Matches the Plunger Speed

- Plunger Movement Stops

- Liquid Continues to Flow

- Liquid Flow Stops

Dispense TADM Curve

Step 1: Enable TADM Recording

TADM is disabled by default. To enable TADM recording for a dispense step, set the tadm_mode property either to TADMMode.ERRORS or TADMMode.ALL.

await hamilton.pipettes.dispense(..., tadm_mode=hamilton.pipettes.TADMMode.ALL)

tadm_limit_curve: int = 0 on the dispense method to choose an appropriate guardband by its index.Step 2: Read TADM Recordings

Each individual channel stores its TADM recordings. Read the data on each channel with get_tadm_data, e.g. for the first channel, use:

tadm_data = await hamilton.pipettes[0].get_tadm_data()

The returned data contains a measured pressure value in Pa for each 10ms.

- Plunger Movement Starts

- Pressure is High Enough to Overcome the Surface Tension and Static Friction

- The Liquid Starts to Flow out of Tip

- The Speed of the Falling Liquid Matches the Plunger Speed

- Plunger Movement Stops

- Liquid Continues to Flow

- Liquid Flow Stops

Conclusion

Incorporating TADM into your liquid handling processes enhances reliability and accuracy, crucial for high-precision applications. By following this guide, you can effectively utilize TADM within your application, ensuring optimal performance in liquid handling tasks.